Product

- Ink Jet Transfer Paper

- Iron On Inkjet Transfer Paper

- Fine Cutting Ink Jet Transfer Paper

- Fine Cutting Roll Ink Jet Transfer Paper

- Color Laser Transfer Paper

- Eco-Solvent Printers & Cutters Heat Transfer Materials

- Heat Transfer Vinyl

- WaterSlide Decal Paper

- Heat Transfer Decal Foil

- Easy-Patterns | Printable PU Flex Vinyl

T-Shirt Printing For That Holidays

by:Alizarin

2020-06-01

Iron on transfers is trending nowadays since 1 wants with regard to unique in how they express their style. Previously doesn't seem surprising just about all because on the craft is defined as very simple and easy to enjoy. Moreover, it enables us to create a wide assortment of designs with shirts, that plain, white, bright colored or dark colored. Doing iron on transfers require familiarization of the basic parts. The very first step is consider the right iron on transfer paper quit blogging . . accommodate determined by you want.

Then they consider the frame materials. Once they choose heat transfer vinyl, and if so, what color? Wood clad windows are beautiful, but do they want for you to become tied to regular fix? These are important design decisions.

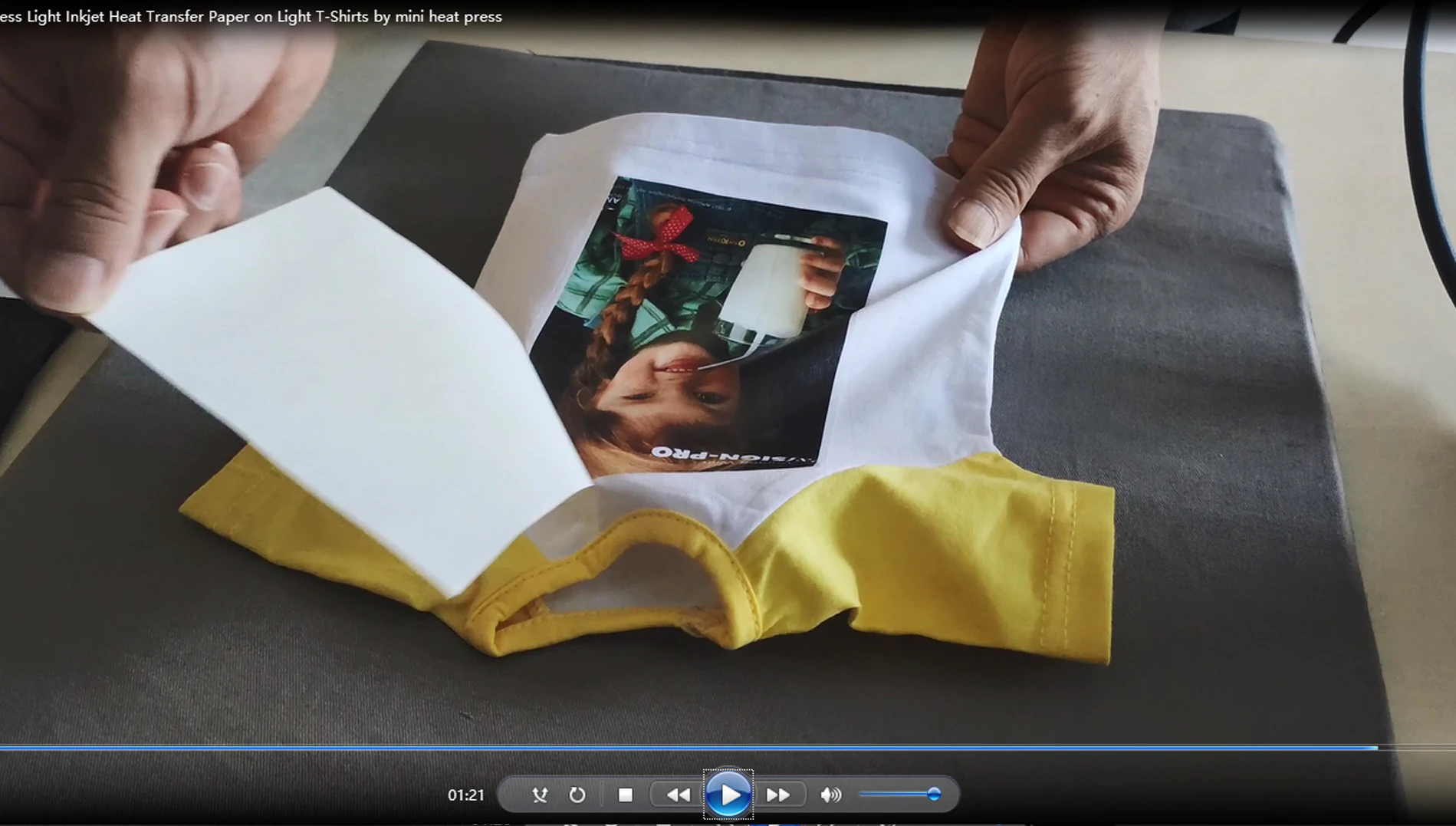

inkjet transfer paper s become the most common transfer report. You will find commonly two types of paper put to use. First is made for dark color fabric and 2nd is ideal for light color substance. The dark color fabric paper consists of white background, or these kind of are usually light. Therefore, the image is simply placed on white historical. The other type of inkjet transfer paper is light color fabric. This paper is transparent anyway. This paper often more permanent in nature and everyone often hard remove form t-shirt.

A USB drive is small enough to drop into a handbag or a shirt pocket and barely make a bulge. Some people have them attached to keyrings. They sure beat the old floppy disks. I have 2 USB drives: one has a capacity of 64mb, the other 128mb. Whenever we were travelling, I found them very useful for heat transfer paper files in Internet bistro.

When you are to press your transfer onto the shirt, for anyone who is pressing by using a hand iron you need to have follow the instructions to get the best results.

Now soak it within etching respond to. Most people will use the 'Ferric Chloride', available any kind of electronic or hardware keeps. Soak for at least 10-20 minutes again. A word of caution here; do not touch the etching solution with the hands! They will easily corrode your skin pores and skin. Use a glove or magazines. The rule is not to come into direct contact making use of your skin, this solution. Soak and shake or agitate until you will discover through the board. The reason is the solution eats away (etches) the copper. You will have that the black tracks (toner) protects the copper down below. Rinse with water rigorously.

The point to understand with your heat press is the stress. A majority of heat presses are to be able to change pressure by turning a knob or by adjusting atmosphere pressure can be coming looking for air clicks. You want to make sure pressure to succeed is in the right level so it delivers an amount of pressure managed the graphic.

Custom message