Product

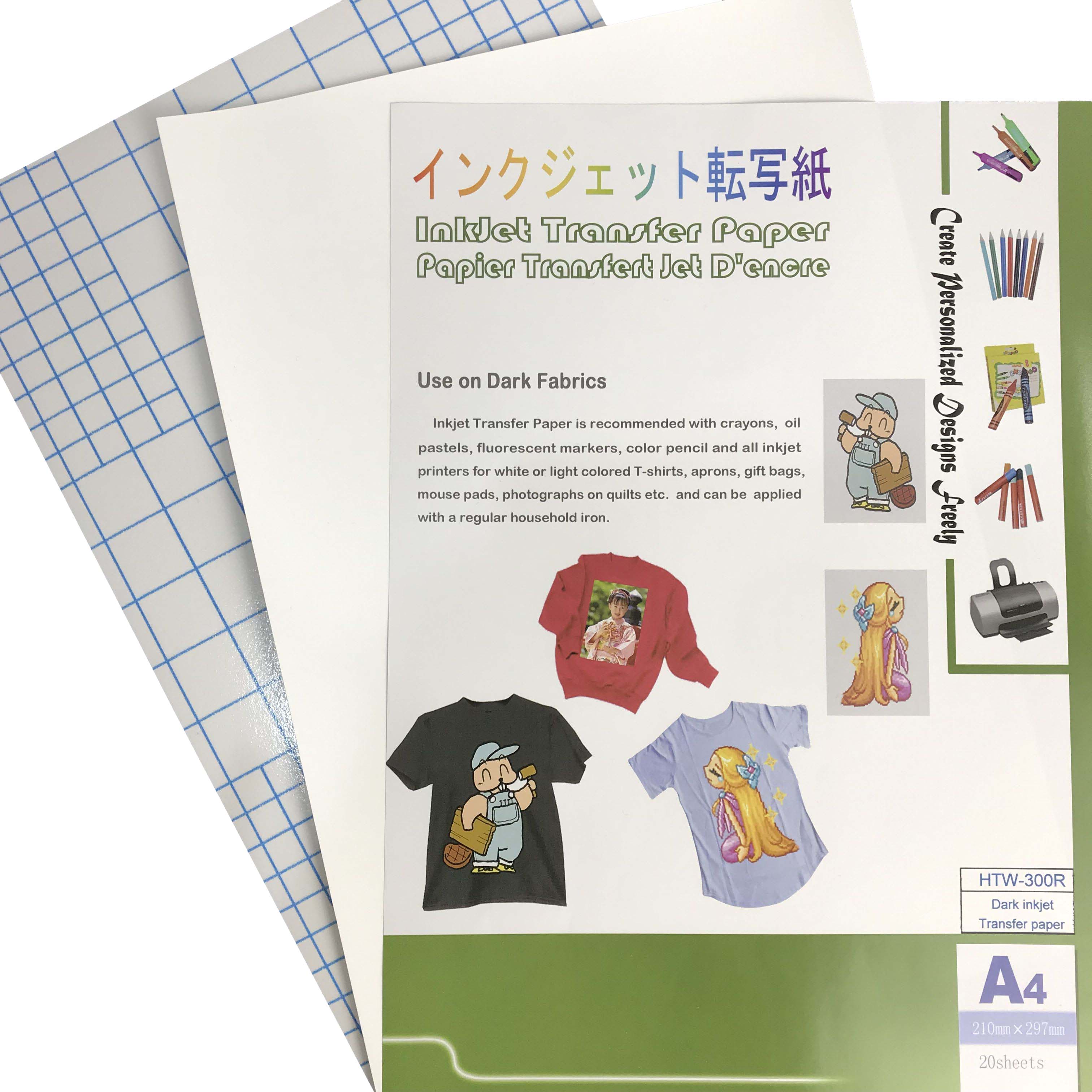

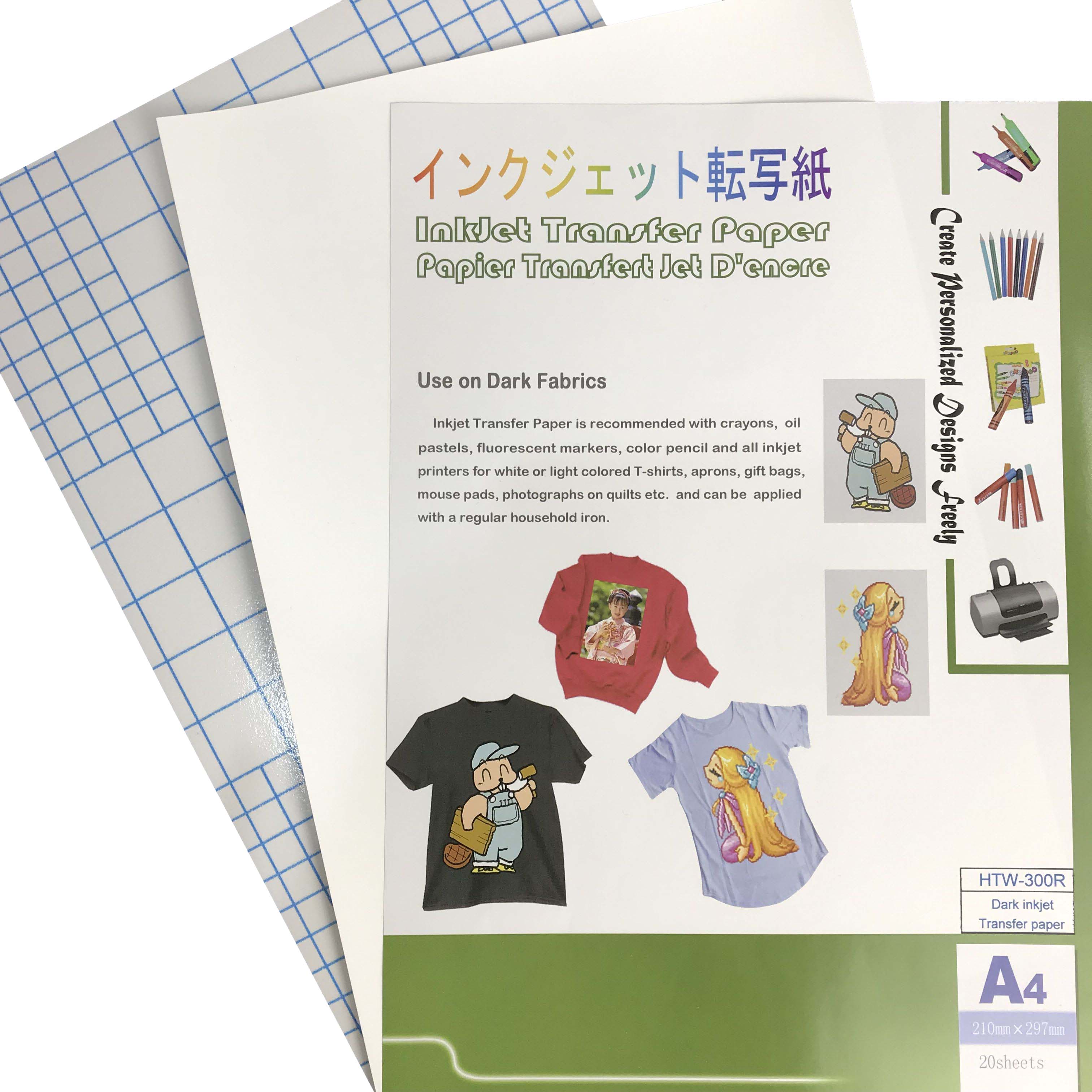

- Ink Jet Transfer Paper

- Iron On Inkjet Transfer Paper

- Fine Cutting Ink Jet Transfer Paper

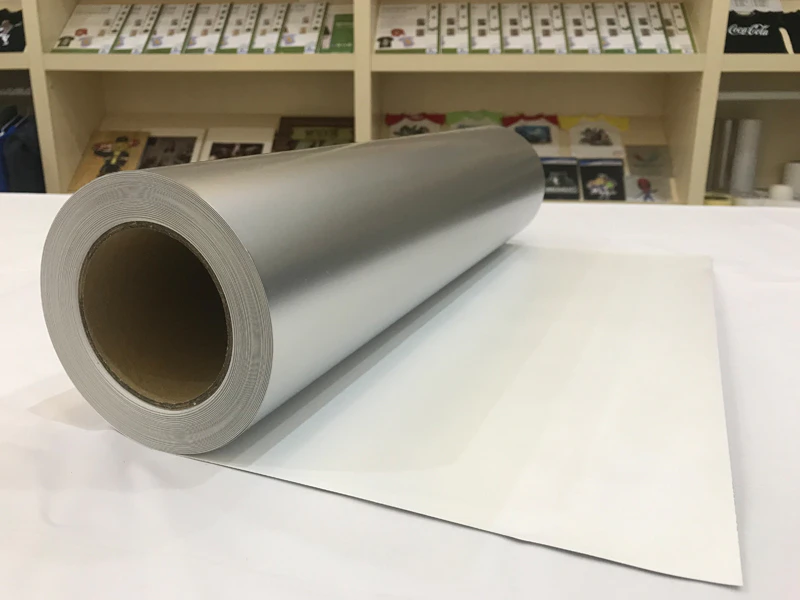

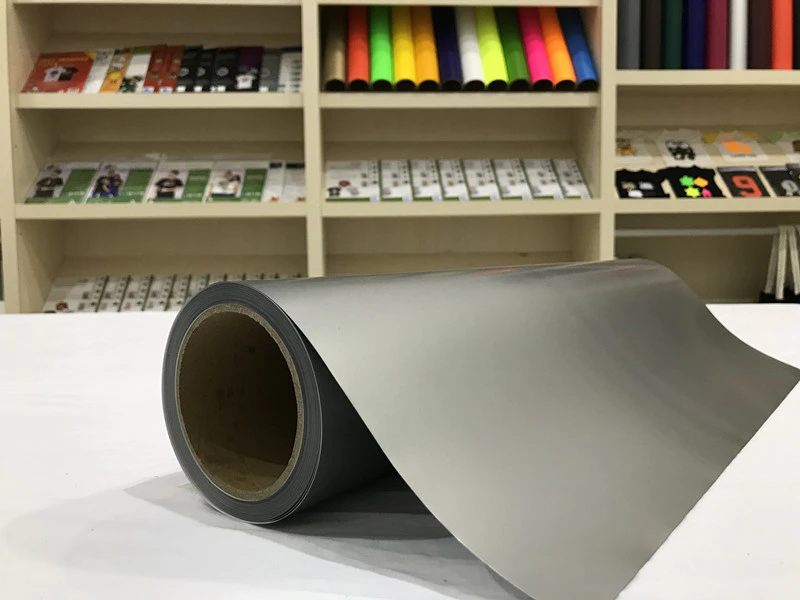

- Fine Cutting Roll Ink Jet Transfer Paper

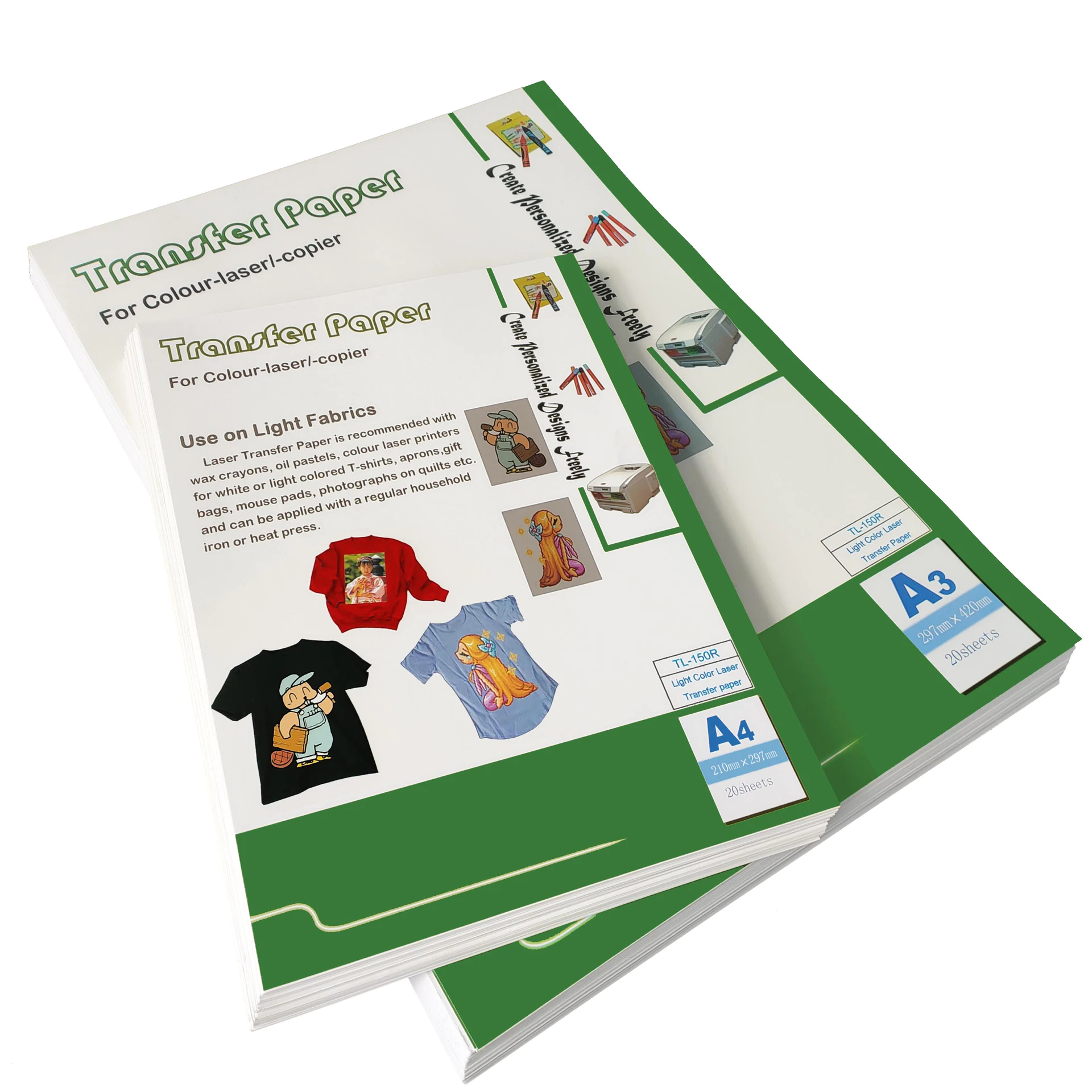

- Color Laser Transfer Paper

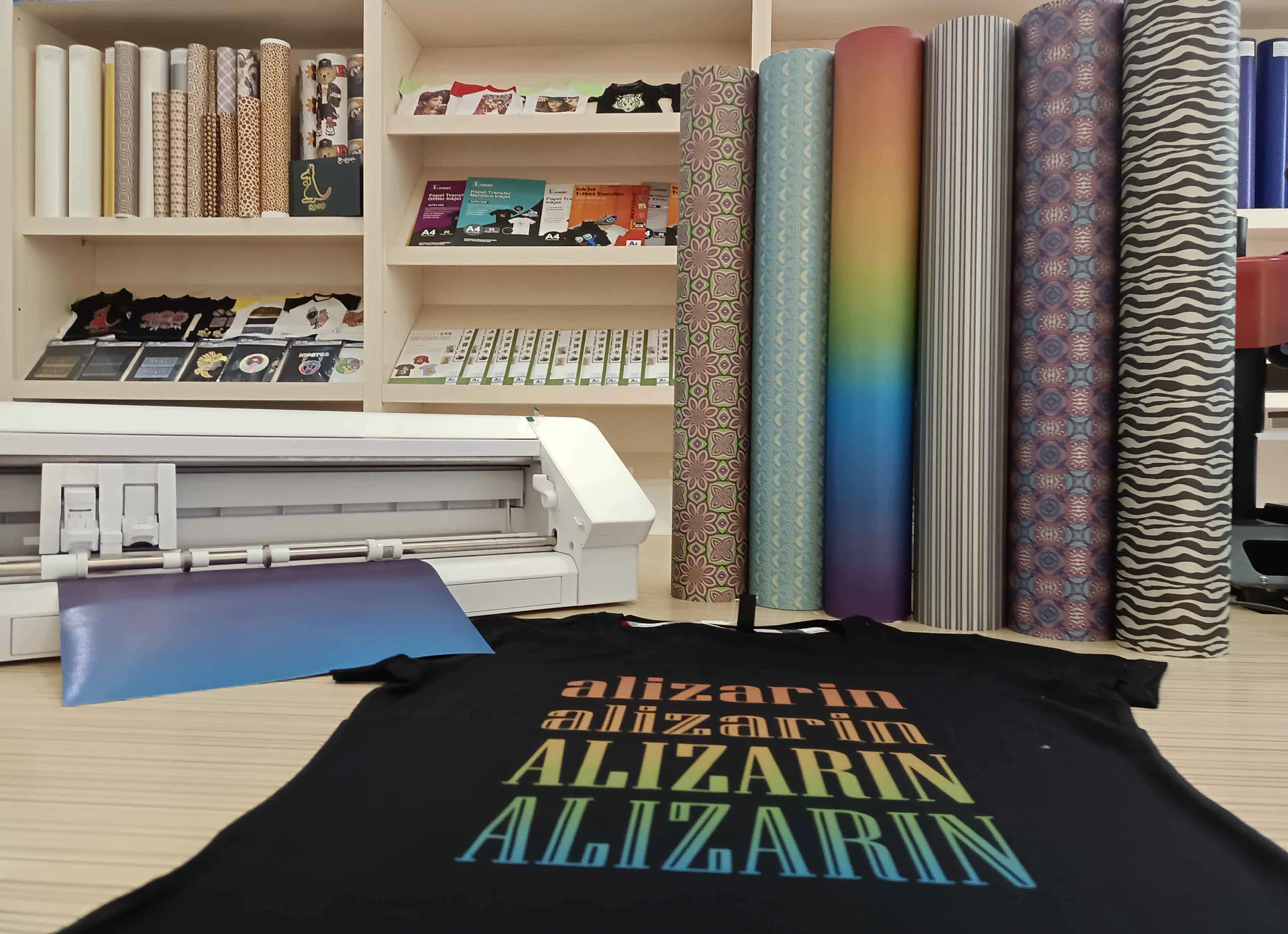

- Eco-Solvent Printers & Cutters Heat Transfer Materials

- Heat Transfer Vinyl

- WaterSlide Decal Paper

- Heat Transfer Decal Foil

- Easy-Patterns | Printable PU Flex Vinyl

200 FAQ

Has inkjet transfer paper passed the QC test?

Has inkjet transfer paper passed the QC test?

2020-09-09

Along with our internal QC testing, Alizarin Coating Co, Ltd. also endeavors to get a third party certification to confirm that the superior quality and functionality of our goods. Our quality management applications are detailed, from the selection of materials for delivery of the finished product. Our inkjet transfer paper is extensively tested to ensure that it meets the highest standards for performance and reliability.

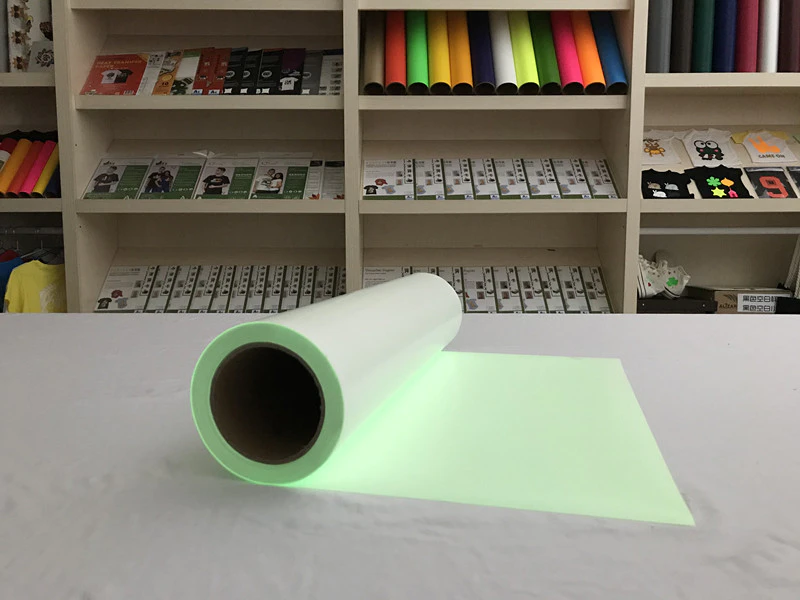

Engaged in the design and manufacture of specialized transfer paper for inkjet, Alizarin is considered one of the top suppliers in China. The inkjet heat transfer paper roll series has become a hot product of Alizarin. The luminous flux of Alizarin glitter vinyl is determined by many parameters, and the higher the luminous flux is, the brighter the lamp bead is. Thus, the luminous flux must be tested by an optical instrument to ensure its accuracy and precision. The product can withstand heat press temperature up to 185°C/365°F. The product causes no injury. Its edges and corners are all rounded and polished to eliminate sharp and irritating burrs. It can be designed into a matte or glossy type.

We have a simple goal: to help our customers become more competitive by manufacturing their products in lower-cost according to the highest established quality standards.

Engaged in the design and manufacture of specialized transfer paper for inkjet, Alizarin is considered one of the top suppliers in China. The inkjet heat transfer paper roll series has become a hot product of Alizarin. The luminous flux of Alizarin glitter vinyl is determined by many parameters, and the higher the luminous flux is, the brighter the lamp bead is. Thus, the luminous flux must be tested by an optical instrument to ensure its accuracy and precision. The product can withstand heat press temperature up to 185°C/365°F. The product causes no injury. Its edges and corners are all rounded and polished to eliminate sharp and irritating burrs. It can be designed into a matte or glossy type.

We have a simple goal: to help our customers become more competitive by manufacturing their products in lower-cost according to the highest established quality standards.

Custom message

Related Products