Product

- Ink Jet Transfer Paper

- Iron On Inkjet Transfer Paper

- Fine Cutting Ink Jet Transfer Paper

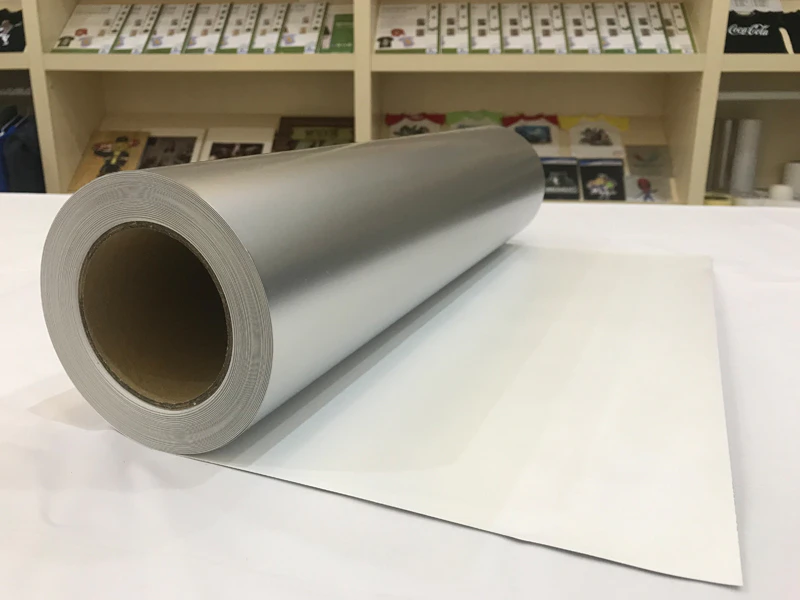

- Fine Cutting Roll Ink Jet Transfer Paper

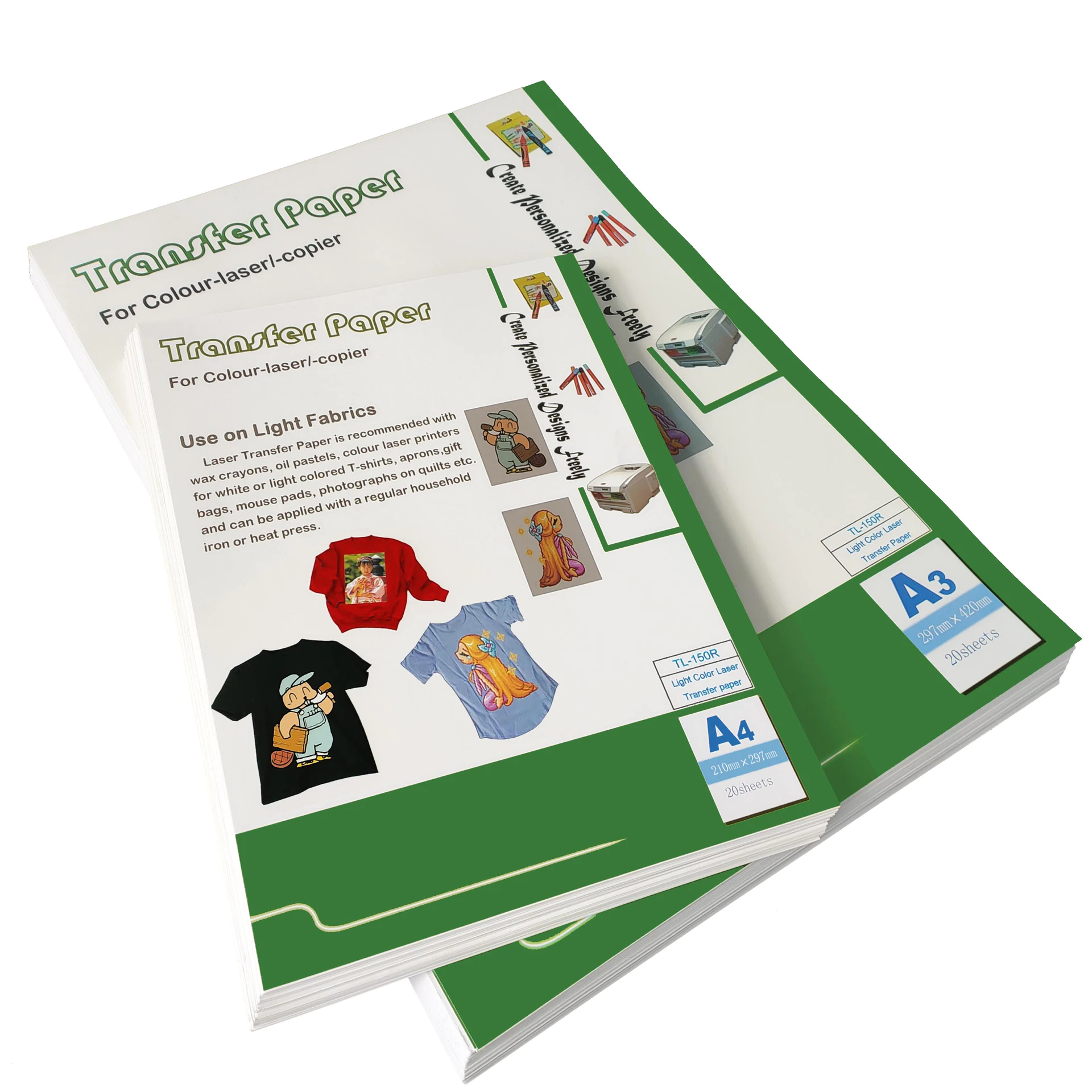

- Color Laser Transfer Paper

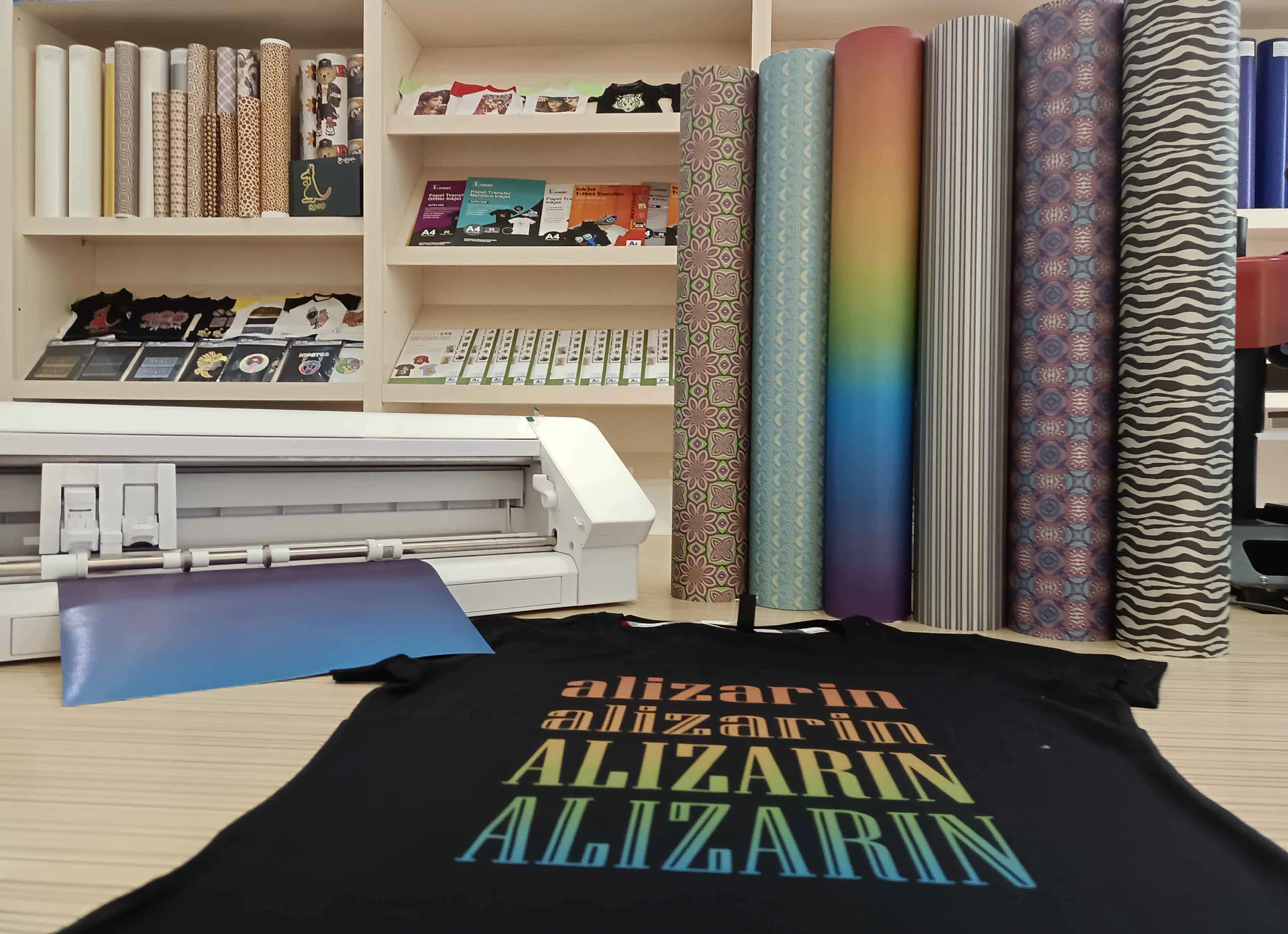

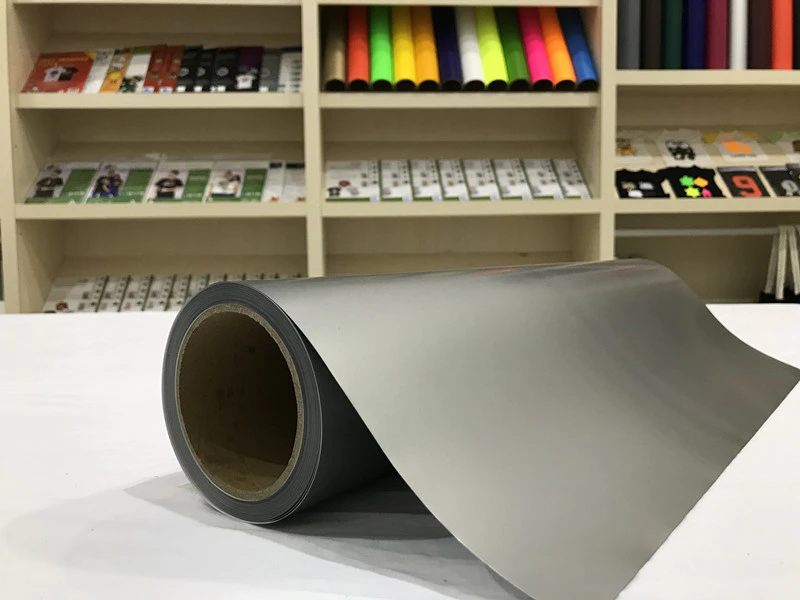

- Eco-Solvent Printers & Cutters Heat Transfer Materials

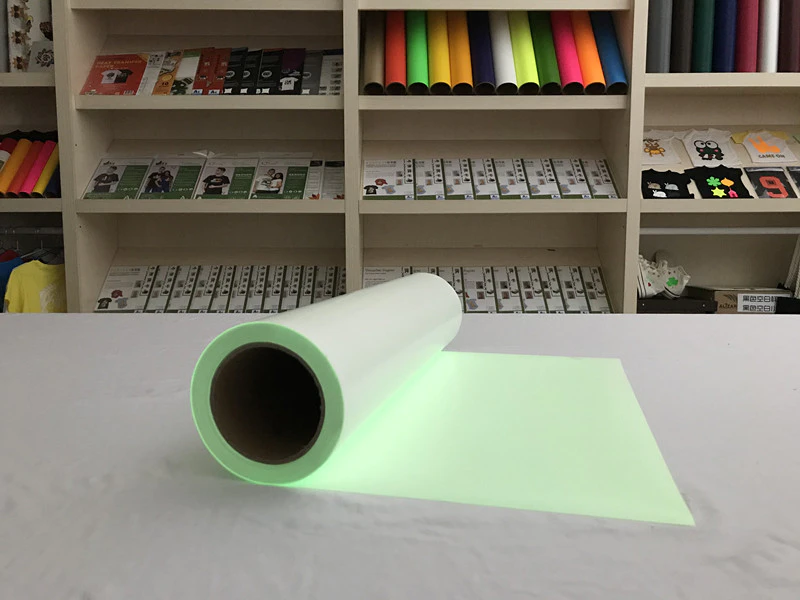

- Heat Transfer Vinyl

- WaterSlide Decal Paper

- Heat Transfer Decal Foil

- Easy-Patterns | Printable PU Flex Vinyl

200 FAQ

How did Alizarin design heat transfer paper roll?

How did Alizarin design heat transfer paper roll?

2020-09-07

The design process of heat transfer paper roll can be finished through 4 steps. Concept developing and product design planning come first. Our designers and technicians work together for the expected product performance and appearance design. The detailed design process comes next. Based on the results of the discussion, our designers should consider the materials processing, target application fields, and user experience comprehensively when conducting the product design rather than focusing on the product shapes, colors, and specifications only. Then, designers will deliver the product drawings or sketches to every department of our company for feedback collecting. The last step is the final confirmation. After reaching a mutual agreement on the product design between customers and us, the product design process is finished and the sample will be made based on the design sketches.

Alizarin Coating Co, Ltd. is a professional high-tech enterprise. As one of Alizarin's multiple product series, inkjet transfer paper series enjoy a relatively high recognition in the market. The materials of Alizarin laser-light (no-cut) have gone through various kinds of tests. They include fire resistance testing, mechanical testing, formaldehyde content testing, and tear strength testing. It can be designed into a matte or glossy type. The product is now widely demanded across various industries, having an extensive applications. The ink absorption ability of this product is strong.

Such business principles and strategic guidelines as glitter vinyl have been formed through the course of Alizarin's development. Check it!

Alizarin Coating Co, Ltd. is a professional high-tech enterprise. As one of Alizarin's multiple product series, inkjet transfer paper series enjoy a relatively high recognition in the market. The materials of Alizarin laser-light (no-cut) have gone through various kinds of tests. They include fire resistance testing, mechanical testing, formaldehyde content testing, and tear strength testing. It can be designed into a matte or glossy type. The product is now widely demanded across various industries, having an extensive applications. The ink absorption ability of this product is strong.

Such business principles and strategic guidelines as glitter vinyl have been formed through the course of Alizarin's development. Check it!

Custom message

Related Products