Product

- Ink Jet Transfer Paper

- Iron On Inkjet Transfer Paper

- Fine Cutting Ink Jet Transfer Paper

- Fine Cutting Roll Ink Jet Transfer Paper

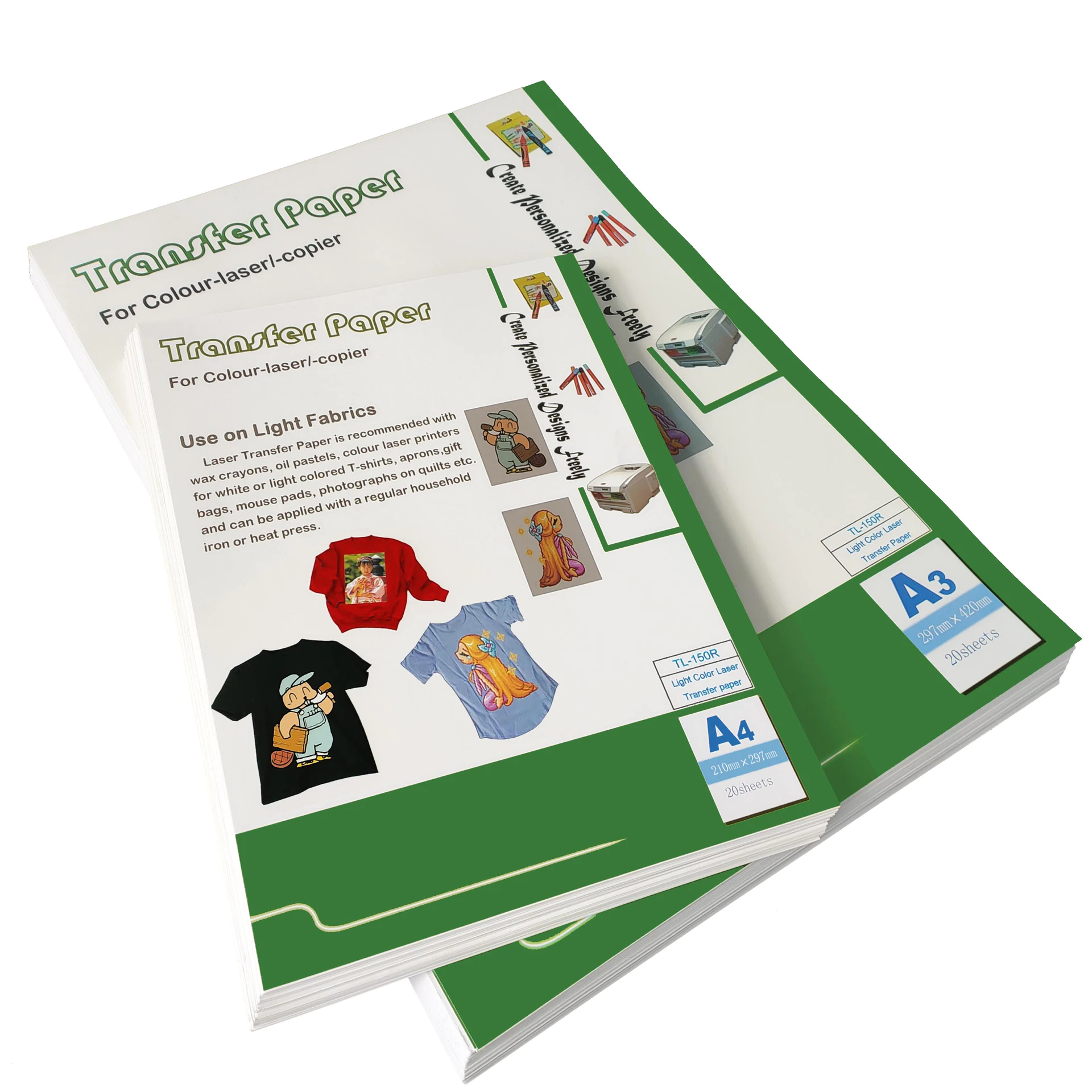

- Color Laser Transfer Paper

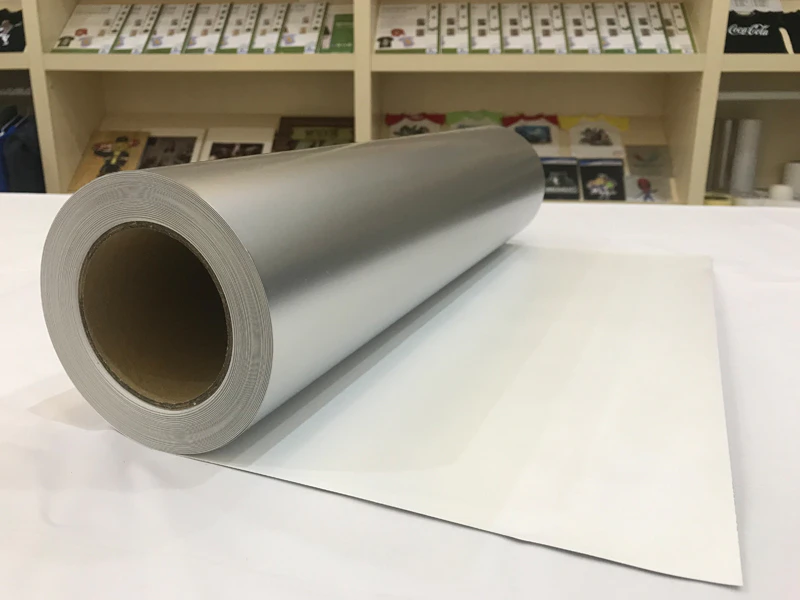

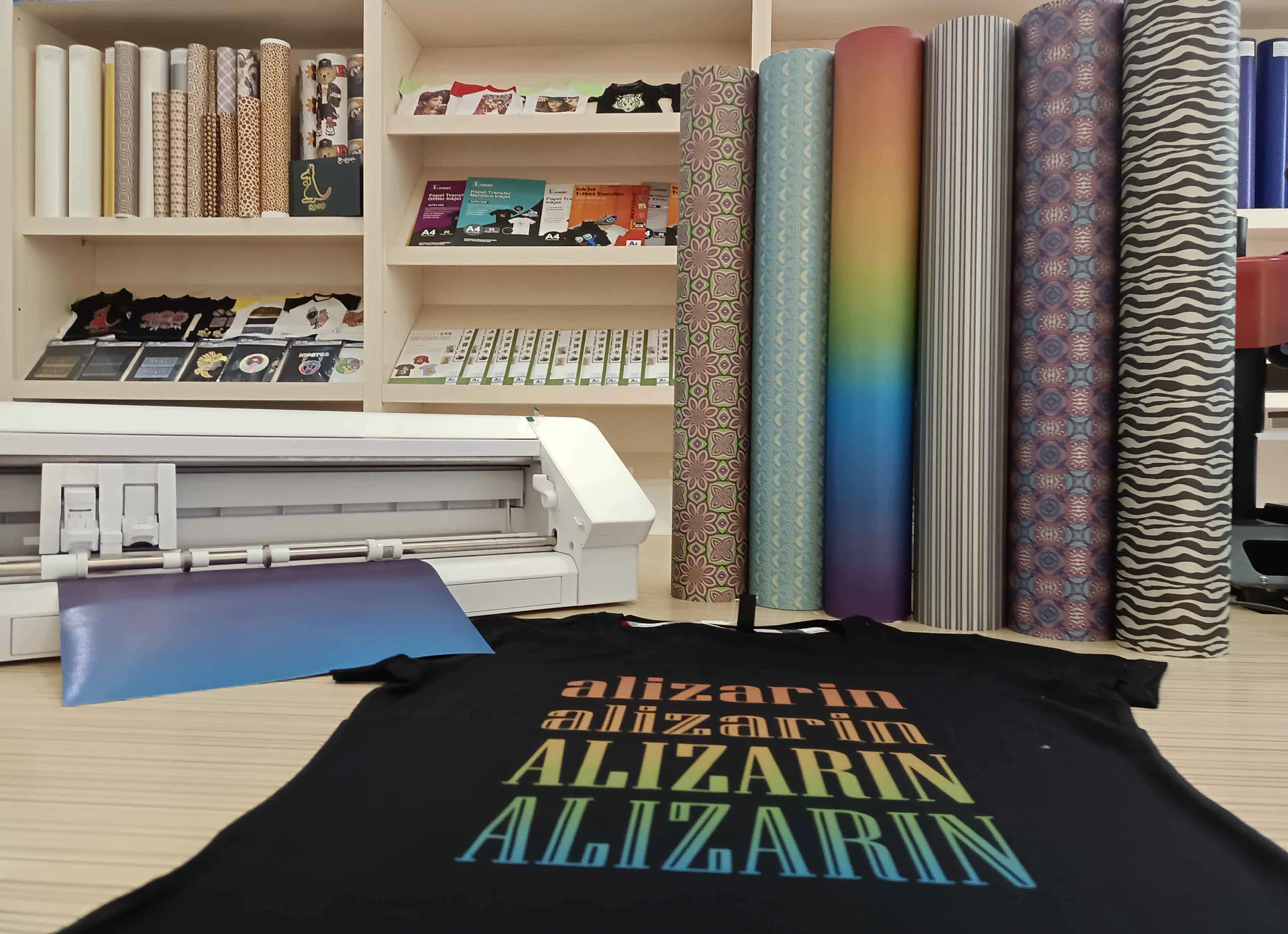

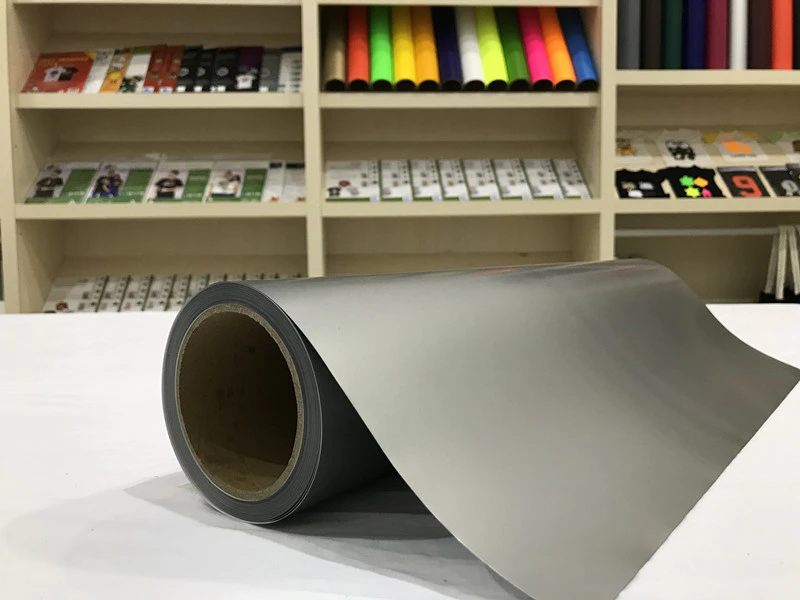

- Eco-Solvent Printers & Cutters Heat Transfer Materials

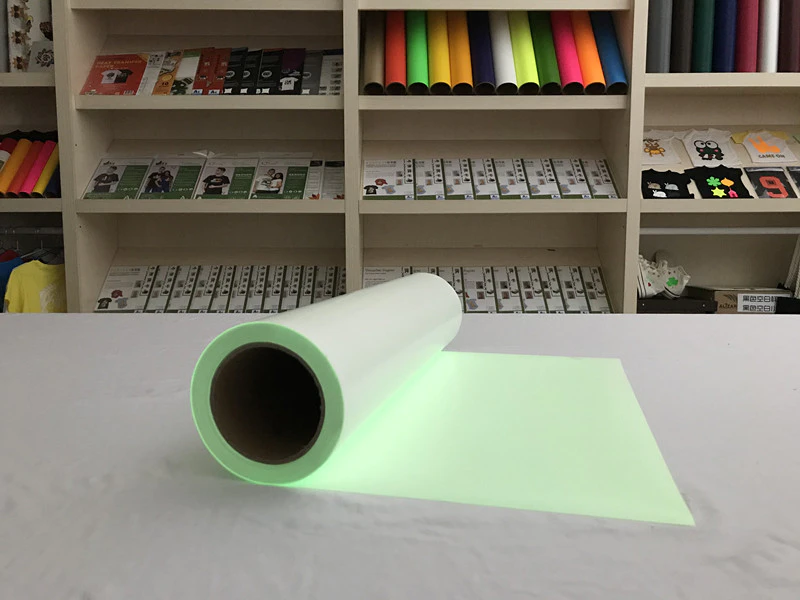

- Heat Transfer Vinyl

- WaterSlide Decal Paper

- Heat Transfer Decal Foil

- Easy-Patterns | Printable PU Flex Vinyl

200 FAQ

How does Alizarin manufacture eco-solvent printable vinyl?

How does Alizarin manufacture eco-solvent printable vinyl?

2020-09-04

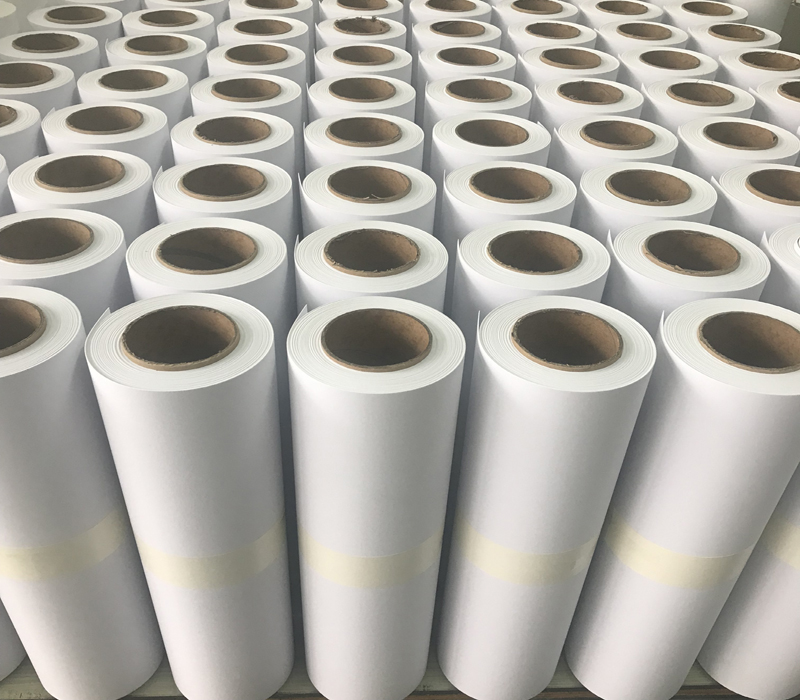

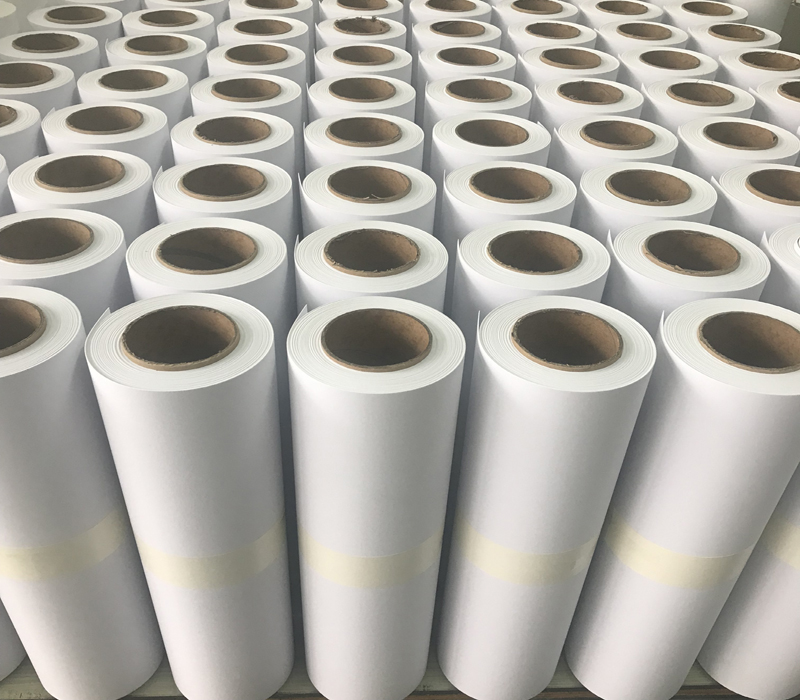

The manufacturing process of bringing eco-solvent printable vinyl to market is long and daunting. At Alizarin Coating Co, Ltd., we utilize a number of methods involving human and machine labor to turn raw materials into finished goods. It starts with communicating with customers to know their exact needs about the products' specifications, colors, shapes, etc. Then, we have creative designers who are responsible for working out the unique appearance and reasonable structure. The next step is to get the customers' confirmation. Then, we work in accordance with the lean management system to streamline the production process and improve work efficiency. Next, quality checks will be performed to ensure the flawless of the products and package process will start at the same time.

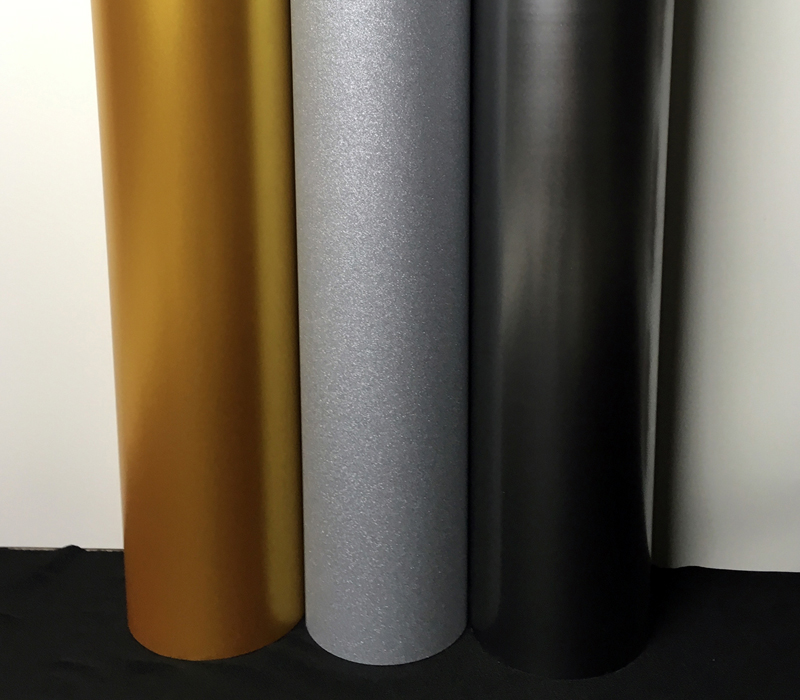

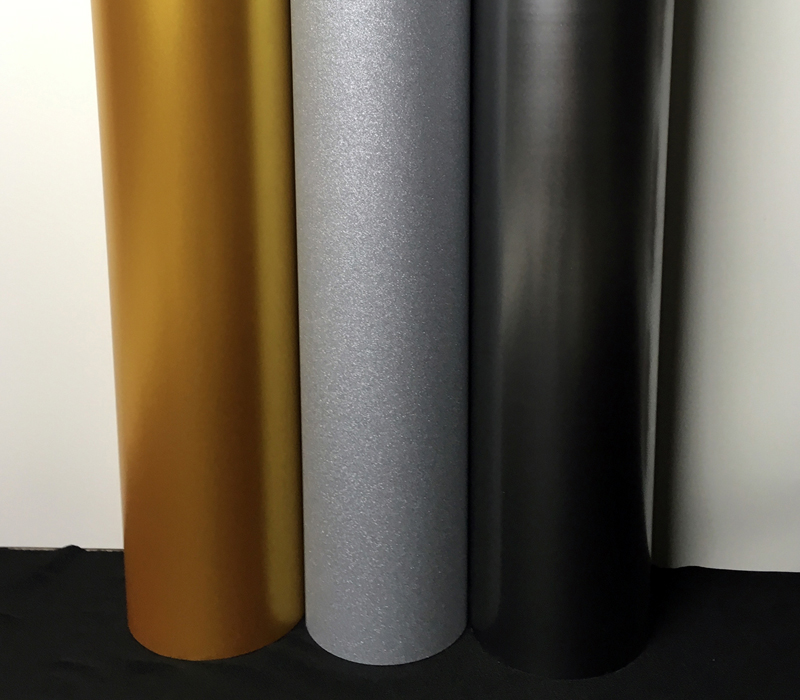

Alizarin is one of the leading producer and distributor of glitter vinyl in the industry. We have accumulated years of experience in production. The eco-solvent printable vinyl series has become a hot product of Alizarin. Unlike capacitive or resistive screen, the screen of Alizarin dark inkjet transfer paper is based on electromagnetic induction technology which is developed by our dedicated R&D staffs. It is especially useful in high-accuracy handwriting or drawing application. This ruggedly handsome product is designed to resist the elements such as impact and rust, making it more time-tested. It can be designed into a matte or glossy type.

We aim to be problem-solvers and partners, not just producers. We listen to customers and make what they want us to make. Then we deliver quickly-- minus any bureaucratic fuss.

Alizarin is one of the leading producer and distributor of glitter vinyl in the industry. We have accumulated years of experience in production. The eco-solvent printable vinyl series has become a hot product of Alizarin. Unlike capacitive or resistive screen, the screen of Alizarin dark inkjet transfer paper is based on electromagnetic induction technology which is developed by our dedicated R&D staffs. It is especially useful in high-accuracy handwriting or drawing application. This ruggedly handsome product is designed to resist the elements such as impact and rust, making it more time-tested. It can be designed into a matte or glossy type.

We aim to be problem-solvers and partners, not just producers. We listen to customers and make what they want us to make. Then we deliver quickly-- minus any bureaucratic fuss.

Custom message

Related Products