Product

- Ink Jet Transfer Paper

- Iron On Inkjet Transfer Paper

- Fine Cutting Ink Jet Transfer Paper

- Fine Cutting Roll Ink Jet Transfer Paper

- Color Laser Transfer Paper

- Eco-Solvent Printers & Cutters Heat Transfer Materials

- Heat Transfer Vinyl

- WaterSlide Decal Paper

- Heat Transfer Decal Foil

- Easy-Patterns | Printable PU Flex Vinyl

Heat Transfer Vinyl Material

by:Alizarin

2020-08-29

Let’s start with the supplies you need after which I’ll present you the way to prepare an iron-on vinyl T-shirt design! Heat transfer vinyl are usually very durable and most of the time, a great high quality vinyl will last longer than the t-shirt itself.

This might be a bed sheet or any other appropriate material that will not transfer any pigment to your garment throughout ironing. An alternative is popping the shirt inside out before ironing. Though vinyl has obtained fairly good heat resistance properties, it won't survive direct heat from an iron field.

Nothing is best than having the ability to label a spice jar, personalize your water bottle, or even create a customized signal. All of these can be made potential with Siser® EasyPSV™ Adhesive Vinyl! But sometimes within the chaos of our initiatives, issues can go incorrect. Not only is it irritating when issues occur, it oftentimes ruins your vinyl and may cost you a lot of money to repair it.

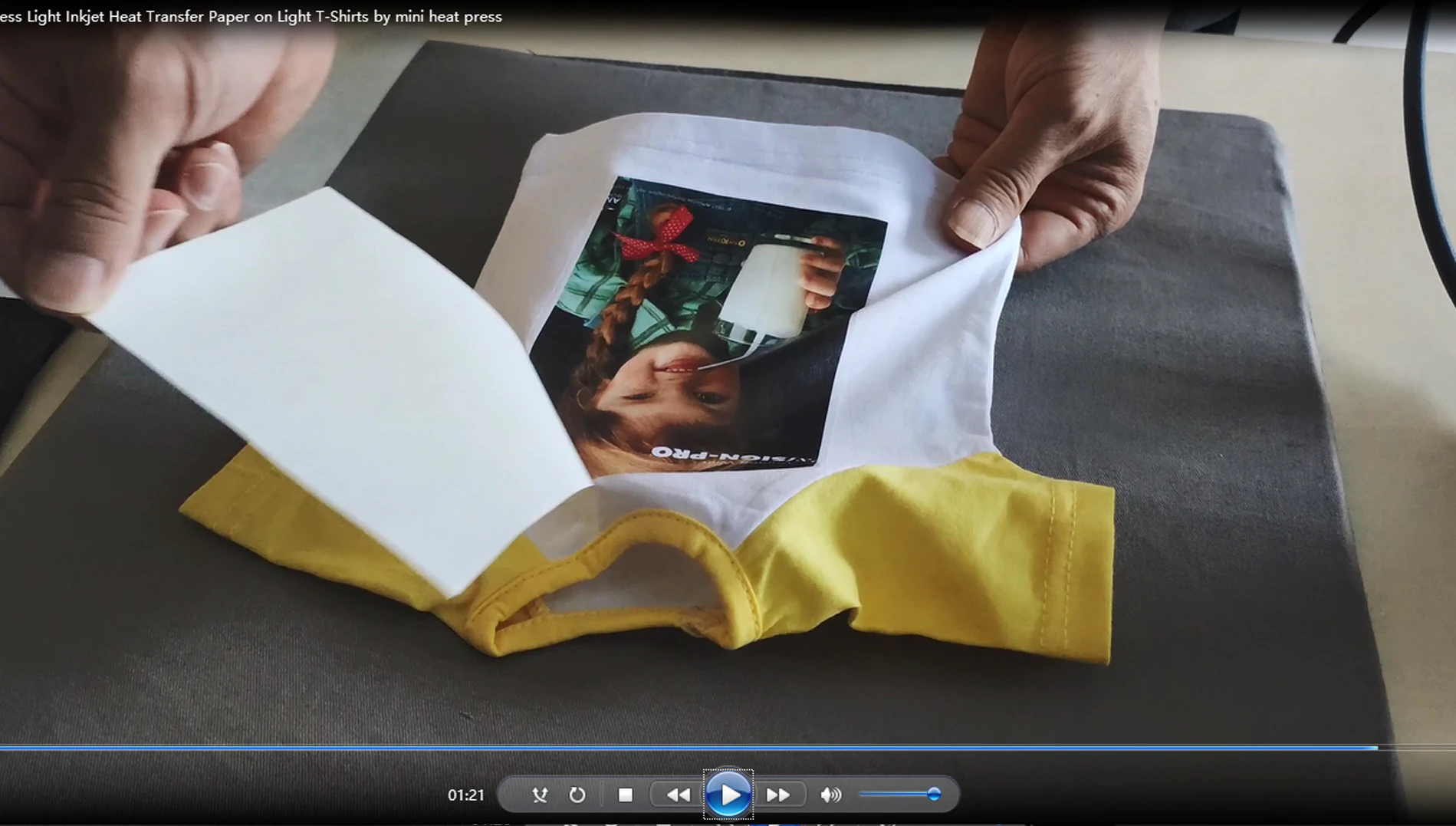

If you could have any issues, you need to use your weeding software to type of pull it away like this. Once you've it began, you just proceed to pull it away from the carrier sheet. And your design will stay on the carrier sheet and the part that you do not need will pull away, identical to this.

You must always protect the print from the same when ironing by placing a protecting layer between the print and the iron. Do not soak your vinyl print garment for long before washing. Soaking loosens the adhesive fairly fast although you may not notice it the first or second time you soak clothes.

Now, whenever you open your shirt you realize exactly where the center is as a result of there's a crease. Just line up the center of the center with the crease. I additionally select to place the design in the top half of the shirt. And now I can get my fingernail underneath the sting of the vinyl easier because of that little knick.

While vinyl has received good resistant properties, the adhesive could not. Exposing the same to heat in washing setting when the fabric is consistently disturbed during washing might trigger the print to peel off.

Don’t neglect – Leave your vinyl decal on the floor for a few minutes and permit the vinyl’s adhesive to bond to the floor. After about minutes, try to pull off the transfer tape once more and see in case you have higher results.

For this project, my design was bigger than my EasyPress. So I needed to slide my EasyPress over to heat the design in two sections. For this project we want to heart it on the entrance. To discover the middle of your shirt, fold it in half by matching up your sleeves. Using your EasyPress or iron, put a little crease on the fold.

Custom message