Product

- Ink Jet Transfer Paper

- Iron On Inkjet Transfer Paper

- Fine Cutting Ink Jet Transfer Paper

- Fine Cutting Roll Ink Jet Transfer Paper

- Color Laser Transfer Paper

- Eco-Solvent Printers & Cutters Heat Transfer Materials

- Heat Transfer Vinyl

- WaterSlide Decal Paper

- Heat Transfer Decal Foil

- Easy-Patterns | Printable PU Flex Vinyl

Heat Transfer Paper

by:Alizarin

2020-09-04

All laser transfers fade over time because of washing, having the denser toner helps with that, doesn't resolve the inevitable fading, but helps the wash performance. However, the 'huge secret' most of us within the pigment ink jet Tshirt business is aware of is that using third party ink for inkjet the ink prices are far cheaper than laser toner prices.

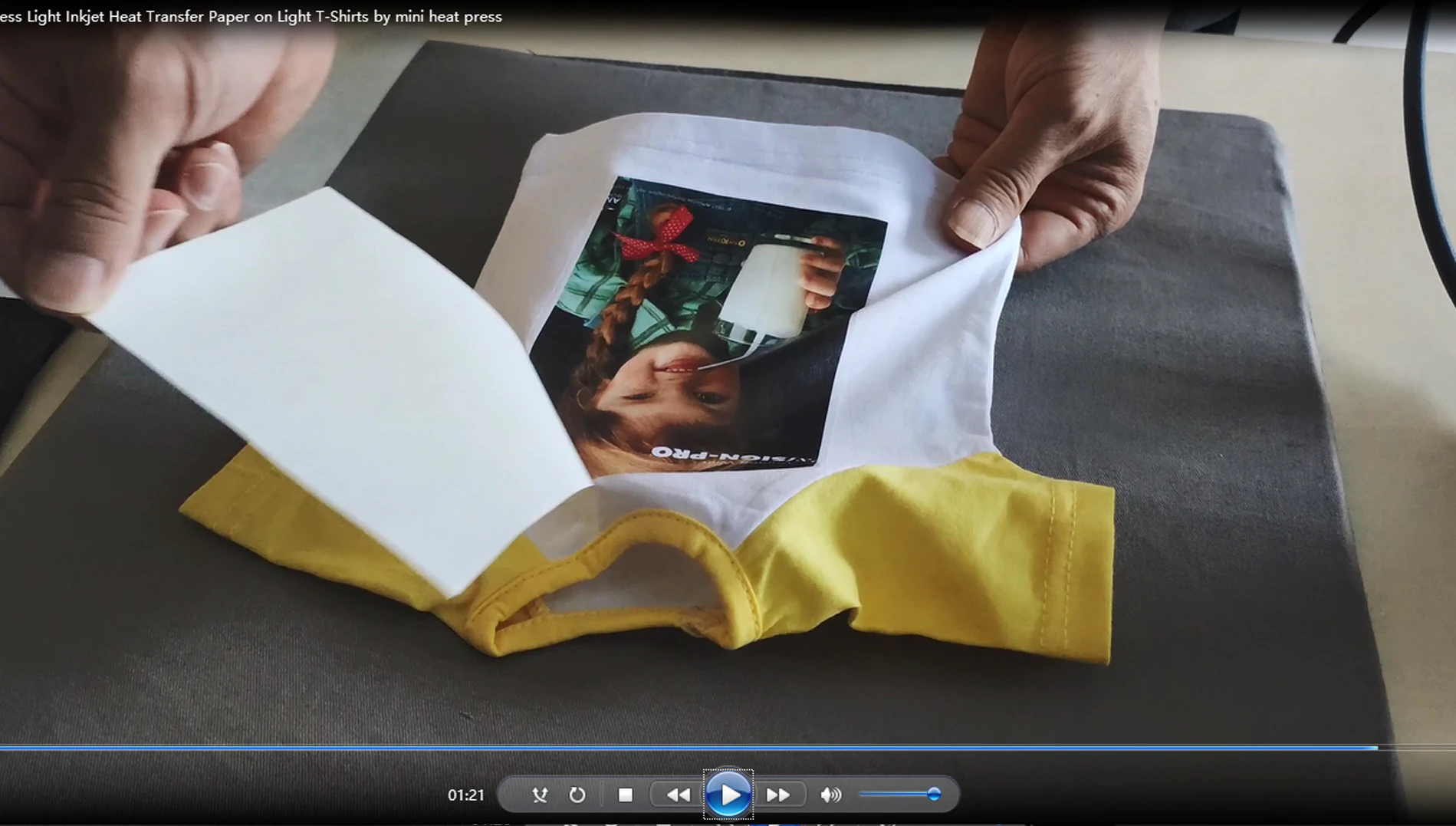

If your ironing surface is sufficiently small, you possibly can slip it contained in the item. Let the second transfer cool, after which remove each backings. Print the transfer, and then reduce off the unprinted areas of the paper leaving a 6.35 mm (1/four in) border across the design.

If you're making use of one other transfer to the opposite facet of a shirt or bag, do not remove the backing from the primary transfer until you could have utilized the second one. To avoid heating the first transfer again, place the item over the ironing surface so that the primary side isn't heated once more.

Epson 'Genuine' carts all the time cheat you slightly and report 'empty' even though you've ink remaining within the cart. There are also occasional head cleans with inkjet which are not applicable to laser. Using CIS or refillables you aren't getting cheated with remaining ink in an 'empty' cart. As of recently most printer manufacturers are utilizing ISO/IEC standards however the actual printed price is all the time referring to finest case printing. The ISO 'commonplace' 5% page is what these producer's claims refer to.

The distinction between these 2 is that the latter is dedicated to providing the right amount of strain and a lot of direct heat for a preset time. This is great as it takes a lot of the guesswork out of it. On the other hand, utilizing an iron requires that you simply apply all these variables manually.

I even have to disagree on the price per print ink jet vs. lasers. This publish is long but I figured to argue this not based on my pure opinion, so I refer to what is published.

Make any adjustments to the standard or the mirror image orientation if necessary. Gather the following items required to print and apply an iron-on transfer. Like with the printing, you test to see how the print will look on a shirt. And then you make no matter modifications are needed based mostly on the result of the samples. Also, you'll be able to have people give their opinion so that you simply provide you with an impeccable result.

Top 10 causes to buy a Stahls Hotronix warmth press. After ironing every part of the transfer, glide the iron as soon as extra over the entire transfer to warmth evenly. four) Print picture/design on paper using the next recommended print settings.

Custom message